Discover how AI-Powered Robotics Automation is transforming enterprise operations, enabling autonomous decision-making, predictive maintenance, human-robot collaboration, and operational intelligence for modern businesses.

Introduction: From Automation to Autonomous Intelligence

AI-Powered Robotics Automation is redefining enterprise operations by moving beyond repetitive tasks into autonomous, adaptive intelligence. Enterprises now deploy robots capable of real-time decision-making, predictive insights, and collaborative workflows, transforming productivity and competitiveness.

-

Introduction: From Automation to Autonomous Intelligence

-

The Strategic Imperative: Why AI Robotics Matters for Enterprises

-

Technical Architecture: The Brain Behind Intelligent Robotics

3.1 Perception

3.2 Cognition

3.3 Action

3.4 Integration Layer -

Real-World Use Cases: AI Robotics in Action

4.1 Manufacturing

4.2 Logistics

4.3 Healthcare

4.4 Smart Factories -

Human-Robot Collaboration: Balancing Autonomy and Safety

-

Predictive Maintenance and Operational Intelligence

-

Strategic Business Value and ROI

-

Emerging Trends in AI Robotics

-

Ethical and Human-Centric Considerations

-

Future Outlook: The Intelligent Robotics Ecosystem Intelligent Robotics Ecosystem

-

Conclusion: The Elegance of Autonomous Intelligence

-

Key Takeaways

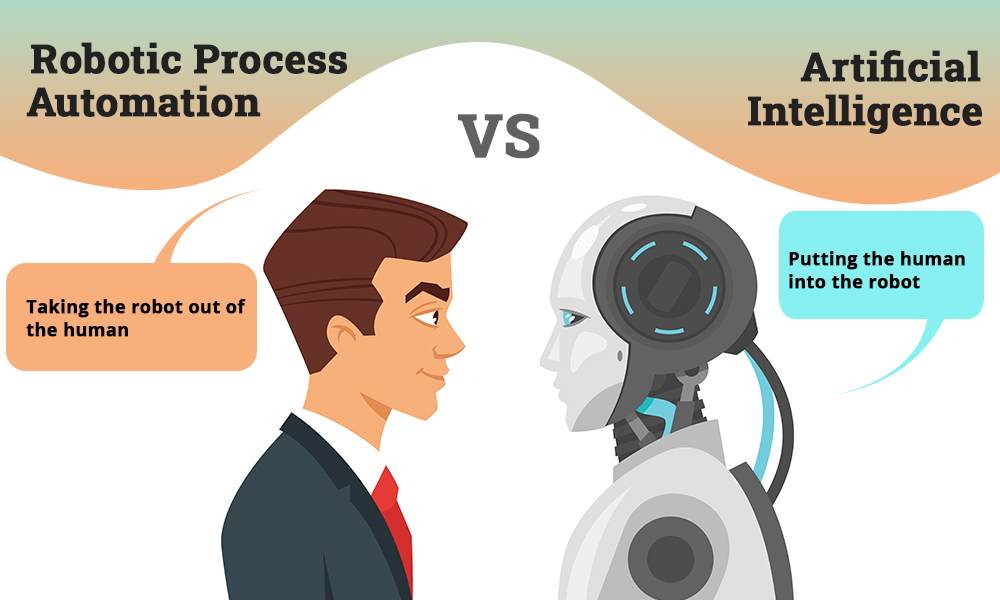

In the evolving landscape of enterprise operations, automation is no longer about repetitive tasks or mechanical efficiency — it is about intelligent autonomy.

Artificial intelligence has transformed robotic systems from programmable machines into adaptive, self-learning operational platforms capable of real-time decision-making, predictive insights, and human-centric collaboration.

Today’s AI-powered robotics redefine not just how enterprises operate, but how they compete, innovate, and build trust in increasingly complex industrial ecosystems. From manufacturing floors to hospital corridors, logistics networks to smart factories, robotics infused with AI is unlocking a new frontier of strategic, operational, and ethical performance.

For enterprises, the question is no longer if to invest in AI-driven robotics — it is how to orchestrate these intelligent systems at scale, safely, and with measurable ROI.

1. The Strategic Imperative: Why AI Robotics Matters for Enterprises

Enterprises that embrace AI-powered robotics gain more than operational efficiency; they gain strategic advantage.

Robotic systems integrated with AI can:

- Optimize productivity while reducing errors and operational risk.

- Deliver real-time adaptive decision-making, adjusting to fluctuations in demand, supply, and environmental conditions.

- Enhance human-robot collaboration, enabling skilled workers to focus on high-value tasks.

- Provide predictive insights for maintenance, resource allocation, and workflow optimization.

Competitive Edge: Companies leveraging AI-driven robots not only reduce costs but create scalable intelligence ecosystems. Operational agility, speed-to-market, and data-driven decision-making become differentiators, positioning them ahead of traditional automation adopters.

Ethical Consideration: With autonomy comes responsibility. Leaders must balance operational efficiency with human safety, workforce impact, and societal trust — embedding ethics into every robotic system from design to deployment.

2. Technical Architecture: The Brain Behind Intelligent Robotics

At the core of AI-powered robotics lies a sophisticated architecture that blends perception, cognition, and action:

Perception

Robots gather and interpret complex data streams from sensors, cameras, LiDAR, and IoT-connected devices. AI algorithms process this data in real time, enabling situational awareness across dynamic environments.

Cognition

Machine learning models allow robots to learn patterns, predict outcomes, and make autonomous decisions. Cognitive layers integrate predictive analytics for maintenance, workflow optimization, and adaptive task planning.

Action

Robotic actuators translate intelligence into precise, context-aware motion. AI ensures accuracy, efficiency, and safety, whether handling fragile materials in a factory or assisting in surgical procedures.

Integration Layer

AI-powered robots operate within broader enterprise ecosystems:

- IoT & Cloud Platforms: Seamless connectivity allows data aggregation, remote monitoring, and fleet-level coordination.

- Digital Twins: Virtual replicas of physical assets enable simulation, predictive maintenance, and scenario testing.

- Edge AI: Localized processing ensures low-latency responses critical for safety and operational continuity.

This architectural synergy ensures that AI-driven robotics are not isolated machines, but intelligent, interconnected enterprise assets.

3. Real-World Use Cases: AI Robotics in Action

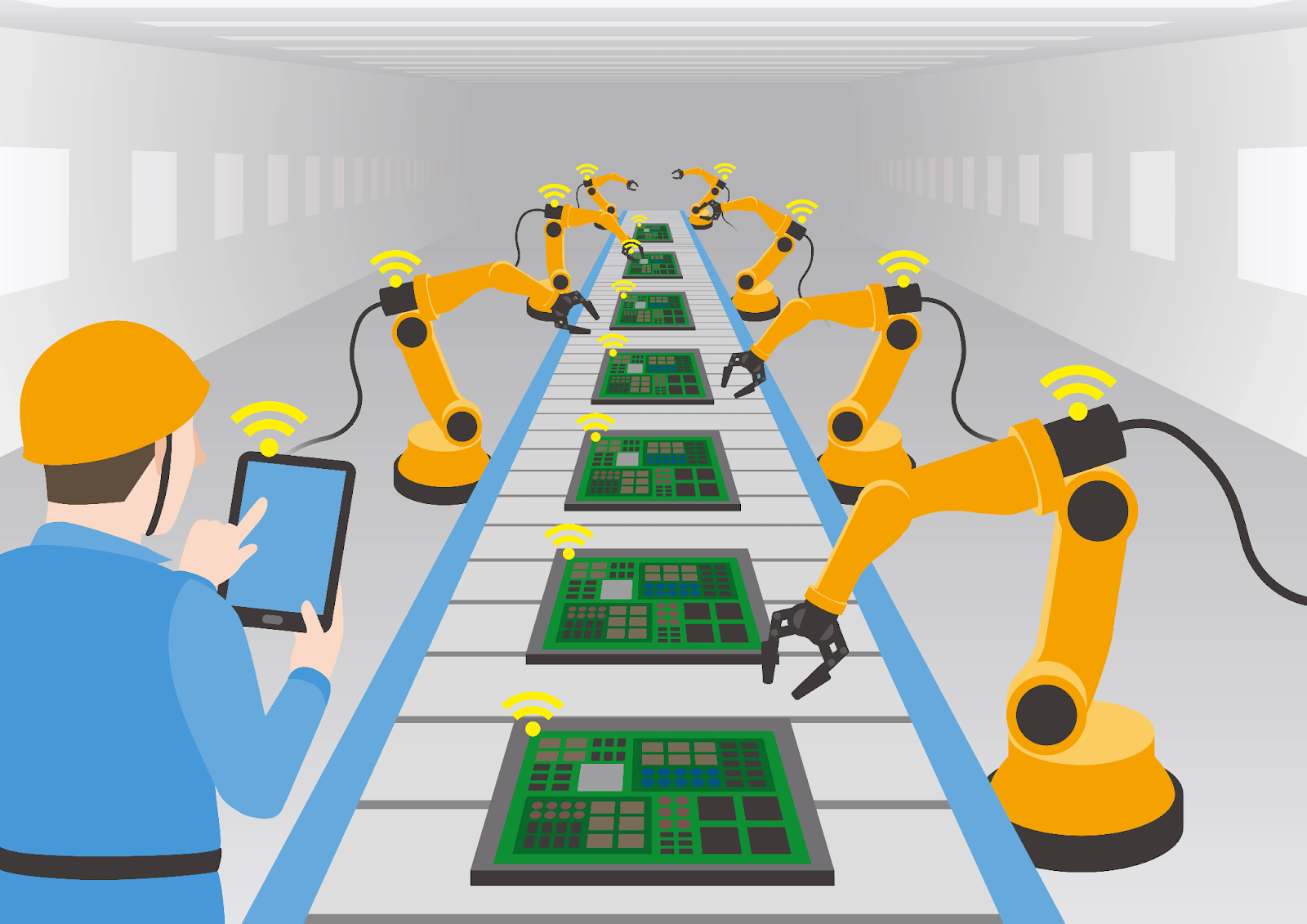

Manufacturing

AI-powered robotic arms optimize production lines with precision, adapt to product variations, and detect defects autonomously.

Example: A luxury automotive manufacturer employs AI-driven cobots to assemble high-value components, reducing production errors by 40% while preserving craftsmanship quality.

Logistics

Robotic fleets equipped with AI route optimization algorithms manage warehouses and delivery networks in real time.

Example: A global e-commerce giant uses AI-driven autonomous robots to pick, pack, and sort packages, increasing throughput while minimizing energy consumption and operational risk.

Healthcare

Surgical robots enhanced with AI provide real-time decision support, adaptive control, and patient-specific procedure optimization.

Example: Hospitals integrating AI-powered robotic assistants reduce surgical complications while improving precision and procedural efficiency.

Smart Factories

Fully automated factories integrate AI, IoT, and robotics to self-optimize production schedules, predictive maintenance, and resource allocation.

Example: A semiconductor plant uses AI to orchestrate robotic wafer handling, dynamically adjusting workflows to maximize yield and reduce energy consumption.

4. Human-Robot Collaboration: Balancing Autonomy and Safety

Autonomy does not replace human expertise — it amplifies it.

AI-powered robotics are increasingly designed for collaborative workspaces, where robots handle repetitive or hazardous tasks while humans contribute strategic thinking, quality assurance, and complex problem-solving.

Key Principles:

- Safety-First Design: AI monitors surroundings and predicts human motion to prevent accidents.

- Adaptive Interaction: Robots learn behavioral patterns to anticipate human actions.

- Ethical Oversight: Humans remain in the loop for critical decisions, ensuring accountability and ethical operation.

This collaborative approach ensures that workforce augmentation is human-centric, safe, and empowering — aligning automation with organizational values.

5. Predictive Maintenance and Operational Intelligence

AI-powered robotics transform maintenance from reactive to predictive:

- Sensor-Driven Monitoring: Continuous telemetry identifies potential wear and anomalies.

- Predictive Analytics: AI models forecast failures before they occur, reducing downtime and repair costs.

- Continuous Optimization: Systems learn from operational data, improving performance, energy efficiency, and safety over time.

Business Impact: Predictive maintenance translates directly into ROI — minimizing downtime, extending equipment lifespan, and enhancing overall productivity.

6. Strategic Business Value and ROI

AI-powered robotics delivers multidimensional value:

- Operational Efficiency: Automated processes reduce cycle times and human error.

- Scalability: Robots adapt to varying production volumes, seasonal demand, and new workflows.

- Cost Reduction: Predictive maintenance, energy optimization, and workforce augmentation reduce operational expenditures.

- Competitive Differentiation: AI robotics enables rapid innovation, quality improvement, and agility unmatched by traditional automation.

Enterprises adopting intelligent robotics are not merely automating — they are redefining industrial intelligence.

7. Emerging Trends in AI Robotics

Collaborative Robots (Cobots)

Robots working alongside humans to augment productivity without replacing expertise.

Edge AI

On-device AI processing for low-latency, secure, and reliable autonomous decisions.

Swarm Robotics

Coordinated robotic fleets that self-organize, optimize paths, and collaborate across tasks — ideal for logistics and large-scale industrial operations.

Autonomous Systems

Fully independent AI-driven machines capable of dynamic problem-solving in unstructured environments.

8. Ethical and Human-Centric Considerations

Ethics and responsibility are integral to AI robotics adoption:

- Workforce Impact: Robots should augment rather than replace skilled labor.

- Safety and Trust: Autonomous systems must be reliable and predictable in complex environments.

- Transparency: AI decision-making should be explainable for operators, auditors, and regulators.

- Environmental Responsibility: Sustainable robotics design reduces energy consumption and operational footprint.

Ethical AI robotics is not optional — it is a prerequisite for long-term enterprise adoption.

9. Future Outlook: The Intelligent Robotics Ecosystem

The next generation of AI-powered robotics will converge autonomy, intelligence, and ethical governance:

- Fully Integrated Digital Twins: Real-time simulations that optimize robotic workflows before physical execution.

- Global Fleet Orchestration: AI coordinates distributed robotic assets across geographies.

- Cognitive Robotics: Machines capable of learning from experience, adapting to novel environments, and collaborating seamlessly with humans.

- Ethical Autonomy: AI systems embedded with moral, safety, and compliance frameworks as part of operational design.

Enterprises that master this ecosystem will command a new paradigm of operational excellence, combining speed, intelligence, and responsibility.

10. Conclusion: The Elegance of Autonomous Intelligence

AI-powered robotics is more than automation; it is intelligent operational artistry.

Enterprises that integrate AI with robotics responsibly unlock not only efficiency but strategic foresight, resilience, and ethical integrity.

The future belongs to organizations that balance autonomy with accountability, innovation with responsibility, and intelligence with human-centric design.

In this era, robotic systems are not just machines — they are partners in enterprise innovation, capable of elevating productivity, safeguarding humans, and delivering measurable business value with conscience and precision.

AI-powered robotics is not the future of automation — it is the future of intelligent enterprise.

Key Takeaways

- AI transforms robotics from automated machines to autonomous, adaptive intelligence.

- Real-time decision-making, predictive maintenance, and human-robot collaboration maximize ROI.

- Ethical, human-centric design is central to sustainable enterprise adoption.

- Emerging trends — cobots, swarm robotics, edge AI — are shaping the next frontier.

- Integration with IoT, cloud platforms, and digital twins ensures operational agility and strategic advantage.